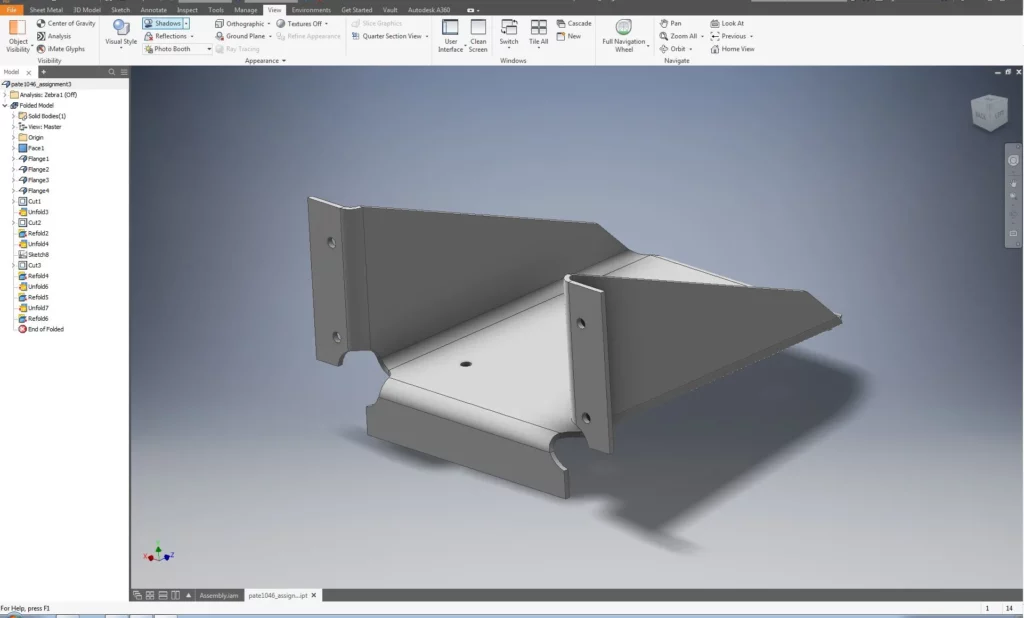

CAD software like Autodesk Inventor makes sheet metal design quick and cost-effective. This course shows designers how to create and edit sheet metal parts, generate flat patterns, and document the designs in drawings.

Objectifs:

This training teaches you how to build sheet metal parts using INVENTOR. Building standalone sheet metal parts, converting parts to sheet metal, and modeling sheet metal parts in the context of an assembly are all topics that are covered in this course.

INVENTOR SHEET METAL TOPICS COVERED:

- Autodesk Inventor Sheet Metal interface

- Sheet metal design process

- Creating base Faces, Contour Flanges, and Contour Rolls

- Creating secondary Faces, Contour Flanges, and Contour Rolls

- Sheet metal parameters

- Creating Flanges

- Creating Hems, Folds, and Bends

- Corner Rounds and Chamfers

- Sheet Metal Cuts (Holes, Cuts, and Punch Features)

- Corner Seams (Seams and Miters)

- Generating Flat Patterns

- Lofted Flanges

- Rips

- Unfolding and Refolding

- Multi-Body Sheet Metal Modeling

- Documentation and Annotation of drawings

- Converting solid models to sheet metal models

- Sheet Metal Styles

AUTODESK INVENTOR Sheetmetal Design Lessons :

Lesson 1: Introduction to Sheet Metal Modeling

- Sheet Metal Concepts

- Sheet Metal Terminology

- Sheet Metal Environment

- Sheet Metal Design Process

Lesson 2: Sheet Metal Base Features

- Applying Existing Sheet Metal Defaults

- Creating a Face as a Base Feature

- Creating a Contour Flange as a Base Feature

- Creating a Contour Roll as a Base Feature

Lesson 3: Sheet Metal Secondary Features

- Sheet Metal Parameters

- Bend Relief Shapes

- Faces as Secondary Features

- Contour Flanges as Secondary Features

- Contour Rolls as Secondary Features

Chapter 4: Flanges

- Creating Flanges

- Corner Relief Options

Chapter 5: Bending Sheet Metal

- Hems

- Folds

- Bends

Chapter 6: Corner Rounds and Chamfers

- Creating Corner Rounds

- Creating Corner Chamfers

Chapter 7: Sheet Metal Cuts

- Creating Cut Features

- Creating Straight Holes

- Using Punch Tool Features

- Creating a Punch Tool

- Cuts Using Surfaces

Chapter 8: Corner Seams

- Creating Corner Seams and Miters

- Creating Corner Rips

- Converting Corner Seams and Bends

Chapter 9: Flat Pattern Environment

- Creating Flat Patterns

- Orienting Flat Patterns

- Punch Representations

- Bend Angle

- Flat Pattern Cleanup

- Exporting to DXF/DWG

Chapter 10: Lofted Flanges and Rips

- Lofted Flange

- Rip

Chapter 11: Unfold and Refold

- Unfold and Refold

Chapter 12: Multi-Body Sheet Metal Modeling

- Multi-Body Modeling

Chapter 13: Documentation and Annotation

- Sheet Metal Drawing Terminology

- Creating Sheet Metal Drawings

- Bend and Punch Notes

- Bend Tables

- Punch Tables

- Bend Order

- Cosmetic Centerlines

Chapter 14: Converting Parts to Sheet Metal

- Converting Solid Models to Sheet Metal

- Non-Ruled Surfaces

| Audience | Designers | |

|---|---|---|

| Language | English – French – Arabic | |

| Prerequisites | The material covered in this training guide assumes a mastery of Autodesk Inventor basics as taught in Autodesk Inventor: Introduction to Solid Modeling. | |

| Duration | 2 Days | |

| Location | On site – Online – Customer site | |

| Software Version | Training is based primarily on INVENTOR 2021. | |

| Level of training | Advanced |

No event found!