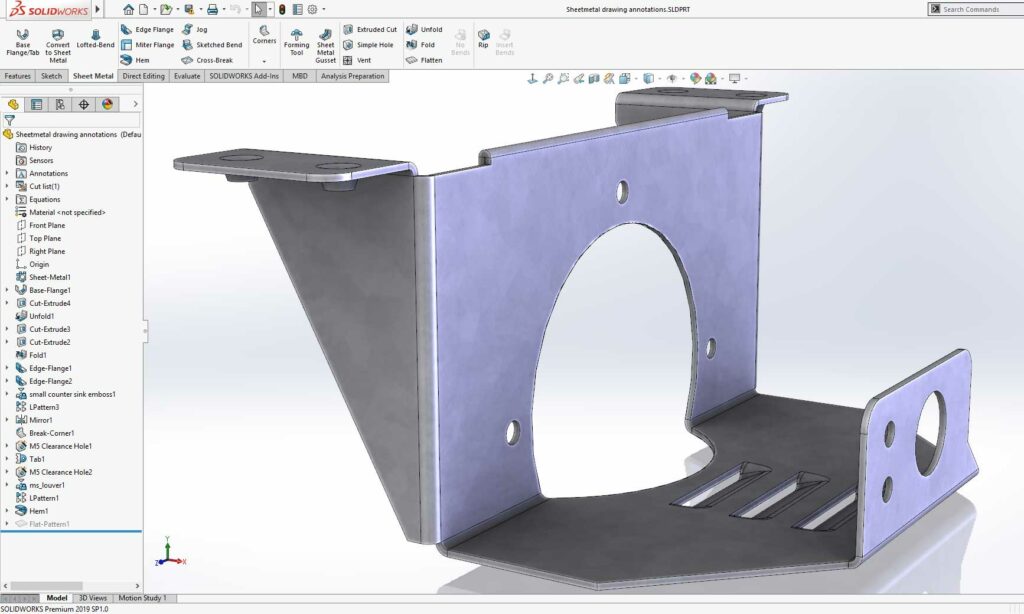

The SOLIDWORKS Sheet Metal course is designed for users who need to learn how to model sheet metal parts that will be manufactured using a variety of forming processes.

You will learn how to build complex sheet metal models (standalone or multibody) by using the various flange features, or converting solid bodies directly into sheet metal parts. The course will also teach you how to apply forming tools, create flat patterns, and how to detail parts in a drawing.

Objectifs:

SOLIDWORKS Sheet Metal teaches you how to build sheet metal parts using SOLIDWORKS. Building standalone sheet metal parts, converting parts to sheet metal, and modeling sheet metal parts in the context of an assembly are all topics that are covered in this course.

SOLIDWORKS SHEET METAL TOPICS COVERED:

- Basic Flange Features

- Working with the Flat Pattern

- Additional Sheet Metal Techniques

- Converting to Sheet Metal

- Multibody Sheet Metal Parts

- Forming Tools and Gussets

- Additional Sheet Metal Functions

SOLIDWORKS Sheetmetal Lessons :

Lesson 1: Basic Flange Features

- What are Sheet Metal Parts?

- Sheet Metal Methods

- Unique Sheet Metal Items

- Flange Method

- Base Flange/Tab

- Sheet Metal Parameters

- What is Bend Allowance?

- Using Tables

- Editing Sheet Metal Parameters

- Sheet Metal Bend Features

- Flat-Pattern Feature

- Flatten and Exit Flatten

- Toggle Flat Display

- Additional Flange Features

- Edge Flanges

- Edge Flange Settings

- Editing the Flange Profile

- Flange Profile Relations

- Edge Flanges on Curved Edges

- Miter Flanges

- Miter Flange Settings

- Hem Feature

- Hem Settings

- Tab Features

- Cuts in Sheet Metal

- Summary of Flange Features

Lesson 2: Working with the Flat Pattern

- Working with the Flat Pattern

- Flat Pattern Settings

- Features for Manufacture

- Corner-Trim Feature

- Corner-Trim Settings

- Corners in the Formed State

- Closed Corner

- Closed Corner Settings

- Corner Relief

- Break Corner/Corner Trim

- Producing the Flat Pattern

- Sheet Metal Cut List Properties

- Accessing Cut List Properties

- Flat Pattern Drawing Views

- Flat Pattern View Properties

- Drawing Document Properties

- Sheet Metal Tables

- Cut List Properties as a Note

- Exporting the Flat Pattern

Lesson 3: Additional Sheet Metal Techniques

- Additional Sheet Metal Methods

- Designing from the Flat

- Sketched Bend Feature

- Jog Feature

- Adding Features in an Unfolded State

- Unfold and Fold

- Creating Cuts in the Flat Pattern

- Swept Flange

- Swept Flange Flat Pattern Options

- Lofted Bends

- Bent Lofted Bends

- Bent Bend Region Options

- Formed Lofted Bends

- Formed Bend Region Options

- Lofted Bends in the Design Library

Lesson 4: Converting to Sheet Metal

- Sheet Metal Conversion

- Insert Bends Method

- Imported Geometry to Sheet Metal

- Adding Rips

- Insert Bends

- Associated Features

- Switching Between States

- Making Changes

- Welded Corner

- Converting Cones and Cylinders

- Convert to Sheet Metal

- Convert to Sheet Metal Settings

- Using Rip Sketches

Lesson 5: Multibody Sheet Metal Parts

- Multibody Sheet Metal Parts

- Tools to Create Multibody Sheet Metal Parts

- Multibodies with Base Flange

- Sheet Metal Parameters for Multibodies

- Solid Body Feature History

- Cut List Item Properties for Multibodies

- Flat Pattern Drawing Views for Multibodies

- Cut List Balloon Annotations

- Exporting to DXF/DWGs with Multibodies

- Convert with Multibodies

- Hiding and Showing Bodies

- Hide and Show

- Hide/Show Bodies

- Isolate

- The Display Pane

- Using Split with Sheet Metal Parts

- Patterning for Multibodies

- Using Edge Flanges to Merge Bodies

- Interfering Bodies

- Combining Sheet Metal with Other Bodies

- Assigning Materials to Bodies

Lesson 6: Forming Tools and Gussets

- Sheet Metal Forming Tools

- How They Work

- Types of Forming Tools

- Standard Forming Tools

- The Forming Tools Folder

- Using a Standard Forming Tool

- Form Tool Feature Settings

- Form Tool Features in the Flat

- Part Document Properties

- Custom Forming Tools

- Split Line

- Forming Tool

- Form Tools in Drawings

- Punch Tables and Punch ID

- Sheet Metal Gusset

Lesson 7: Additional Sheet Metal Functions

- Additional Sheet Metal Functions

- Cross-Breaks

- Cross Break Settings

- Vent Features

- Mirror Part

- Tab and Slot

- Process Plans

- Sheet Metal Costing

| Audience | Designers | |

|---|---|---|

| Language | English – French – Arabic | |

| Prerequisites | SOLIDWORKS Essentials or Certified SOLIDWORKS Associate (CSWA) | |

| Duration | 2 Days | |

| Location | On site – Online – Customer site | |

| Software Version | Training is based primarily on SolidWorks 2021. It is relevant to users of SolidWorks 2016 and later. | |

| Level of training | Advanced |